Croatian Center of Renewable Energy Sources (CCRES)

promotes some

REC Solar

REC AE-US Series PV modulesThe

REC AE-US Series modules, made in Sweden by REC, are a series of high

quality solar modules designed to meet system demand for exceptional

performance.

REC AE-US Series PV modulesThe

REC AE-US Series modules, made in Sweden by REC, are a series of high

quality solar modules designed to meet system demand for exceptional

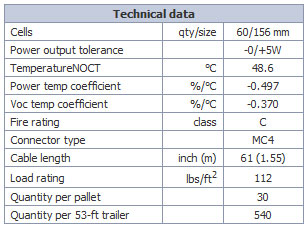

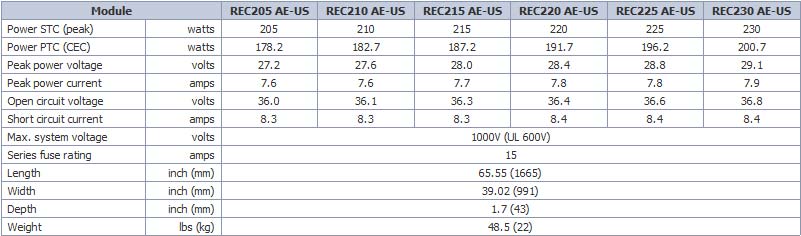

performance.- Quality and PerformanceRigorous quality control is applied throughout the production process, from cells to modules. Sixty 156 mm square multicrystalline solar cells in each module are optimized for low light conditions and increased light absorption. The modules have an innovative design that reduces shading effects in order to achieve maximum performance. A power output tolerance of -0/+5W guarantees minimum mismatch losses.

- InstallationREC AE-US Series allows for quick and easy installation. The modules are equipped with PV Wire cables with MC4 locking connectors for problem-free inter-module connection. Cables meet 2008 NEC requirements for use with transformerless inverters.

- Environmental PracticesThe REC AE-US Series generates environmentally sound electricity. Cell and module production processes are designed to maximize recycling and reduce environmental impact. REC’s wafers, cells and modules are produced within Scandinavia and the company’s activities are therefore subject to very high standards of regulation regarding environmental standards.

Warranty

The REC AE-US Series comes with a 63-month workmanship

warranty and a guarantee of 90% of rated power output for 10 years, and

80% of rated power output for 25 years.

Warranty

The REC AE-US Series comes with a 63-month workmanship

warranty and a guarantee of 90% of rated power output for 10 years, and

80% of rated power output for 25 years.

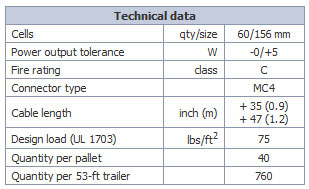

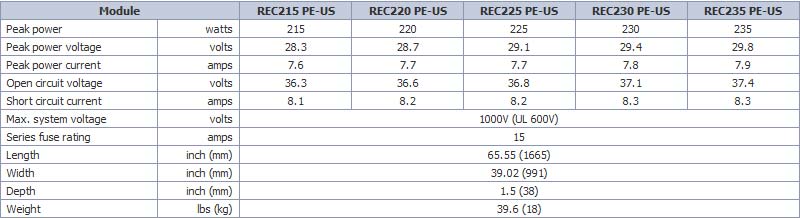

PE-US Series PV modulesThe

REC PE-US Series modules, made by REC in Singapore, are a series of

high quality solar modules designed to meet system demand for

exceptional performance.

PE-US Series PV modulesThe

REC PE-US Series modules, made by REC in Singapore, are a series of

high quality solar modules designed to meet system demand for

exceptional performance. -

Quality and PerformanceRigorous

quality control is applied throughout the production process, from

cells to modules. Sixty acid-etched, 3-busbar, 156 mm square

multicrystalline solar cells laminated behind high-transparency glass

with an anti-reflective surface treatment give these modules an

efficiency of up to 14.2%. A power output tolerance of -0/+5W guarantees

you the power you pay for and minimum mismatch losses.

The REC PE-US Series modules are made with silicon refined in the U.S. using renewable energy. Their energy payback is under one year and their cell and module production processes are designed to maximize recycling and reduce environmental impact. - InstallationThe comparatively low weight (39.6 lbs/18 kg) of the REC PE-US Series allows for quick and easy installation. The modules are equipped with an environmentally sealed junction box and PV Wire cables with MC4 locking connectors for problem-free inter-module connection. Cables meet 2008 NEC requirements for use with transformerless inverters.

Warranty

The REC PE-US Series modules come with a 63-month

workmanship warranty and a guarantee of 90% of rated power output for 10

years, and 80% of rated power output for 25 years.

Warranty

The REC PE-US Series modules come with a 63-month

workmanship warranty and a guarantee of 90% of rated power output for 10

years, and 80% of rated power output for 25 years.

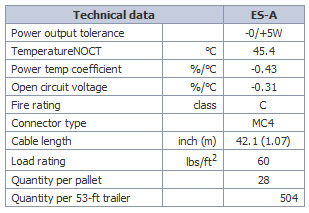

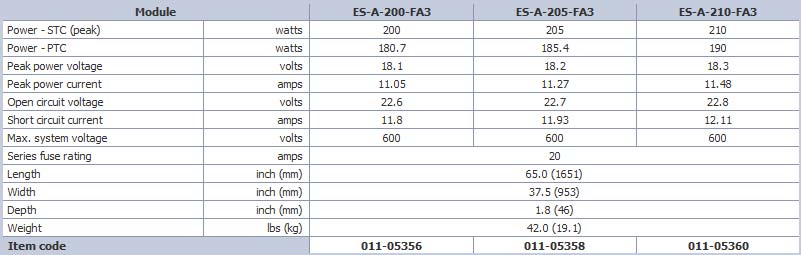

Evergreen Solar

ES-A Modules

Evergreen Solar modules are designed to deliver the best

performance and dependability from Evergreen Solar’s patented String

Ribbon wafer technology. These modules have one of the tightest power

tolerances in the industry.

ES-A Modules

Evergreen Solar modules are designed to deliver the best

performance and dependability from Evergreen Solar’s patented String

Ribbon wafer technology. These modules have one of the tightest power

tolerances in the industry.-

Performance

Maximum power up to 5W above rated.

Anti-reflection cover glass delivers more energy.

A rigid, double-walled, deep frame with integrated water drainage holes

Crimped frame corners – no screws to loosen

Sealed junction box on ES-A modules never needs field maintenance

-

Environmental Credentials

A rigid, double-walled, deep frame with integrated water drainage holes

Crimped frame corners – no screws to loosen

Sealed junction box on ES-A modules never needs field maintenance

PV modules produced by Evergreen Solar are distinctive in their appearance because they incorporate a proprietary crystalline silicon technology known as String Ribbon. In the String Ribbon technique, two high-temperature strings are pulled vertically through a shallow silicon melt, and the molten silicon spans and freezes between the strings. The process is continuous: long strings are unwound from spools; the melt is replenished; and the silicon ribbon is cut to length for further processing, without interrupting growth.  Evergreen

ES-A modules utilize three parallel strings of 38 cells in series

giving an 18-volt peak power voltage which allows fewer strings in

grid-tie systems and also provides optimum voltage for battery charging

with conventional as well as MPPT charge controllers. They have

Multi-Contact MC4 locking connectors, PV Wire, and black anodized

frames. Made in USA.

Evergreen

ES-A modules utilize three parallel strings of 38 cells in series

giving an 18-volt peak power voltage which allows fewer strings in

grid-tie systems and also provides optimum voltage for battery charging

with conventional as well as MPPT charge controllers. They have

Multi-Contact MC4 locking connectors, PV Wire, and black anodized

frames. Made in USA.

- Evergreen modules are ETL listed to UL 1703 for U.S. and Canada. Modules have a 10-year 90% power warranty, 25-year 80% power warranty.

Sharp Solar

Sharp Solar Basics

For 48 years, Sharp has led the industry with practical,

efficient, and affordable solar electric systems. Sharp systems have

been installed everywhere, from the demanding environments of satellites

and lighthouses to commercial and industrial buildings, and even on the

most beautiful, high-tech homes. Solar has come a long way since 1954

when the first solar cell was created. Yet, the basic principles of

solar technology remain the same.

Sharp Solar Basics

For 48 years, Sharp has led the industry with practical,

efficient, and affordable solar electric systems. Sharp systems have

been installed everywhere, from the demanding environments of satellites

and lighthouses to commercial and industrial buildings, and even on the

most beautiful, high-tech homes. Solar has come a long way since 1954

when the first solar cell was created. Yet, the basic principles of

solar technology remain the same.

- The Economical and Ecological ChoiceSharp is the #1 manufacturer of solar cells worldwide with nearly as much generating capacity as the next three largest manufacturers combined. They're cost-effective, quiet, attractive, safe, and reliable, with only minimal maintenance required over their long operational life. They're the right choice for your home and the right choice for the environment. It's no wonder why so many homeowners are making the move to Sharp Solar.

- Tomorrow's Energy TodayImagine solar electricity not only powering businesses, large-scale utilities and neighborhoods, but also billboards, street lamps and portable electronics. Sharp's commitment towards environment-friendly products brings you tomorrow's energy today.

Trina Solar

Overview

Trina Solar Limited (TSL) is an internationally

recognized manufacturer of mono and multicrystalline photovoltaic (PV)

modules and has a long history as a solar PV pioneer since it was

founded in 1997 as a system installation company in China. Our

high-quality PV modules provide clean and reliable solar electric power

to on-grid and off-grid residential, commercial, industrial and utility

scale applications around the world. With local sales and marketing

offices as well as installation partners throughout Asia, Europe and

North-America, Trina Solar is committed to improving the competitiveness

and efficiency of solar energy and developing a sustainable PV

industry.

Overview

Trina Solar Limited (TSL) is an internationally

recognized manufacturer of mono and multicrystalline photovoltaic (PV)

modules and has a long history as a solar PV pioneer since it was

founded in 1997 as a system installation company in China. Our

high-quality PV modules provide clean and reliable solar electric power

to on-grid and off-grid residential, commercial, industrial and utility

scale applications around the world. With local sales and marketing

offices as well as installation partners throughout Asia, Europe and

North-America, Trina Solar is committed to improving the competitiveness

and efficiency of solar energy and developing a sustainable PV

industry.

-

Trina Solar celebrated its 10th year

Anniversary on April 22, 2008 in China with more than 800 guests from

all over the world. The achievements of the last decade have laid a

solid foundation for Trina's accelerated growth, and the global

alternative energy development potential ensures Trina Solar an even

brighter future. The company will continue to be dedicated to

innovation, quality and improved efficiencies as it pursues grid parity

to expand the global solar PV industry.

What We Do - Trina Solar research, development and manufacturing of ingots, wafers, cells and solar modules are conducted at its facilities in Changzhou, China, where Trina Solar occupies a site of approximately 152,526 square meters. Trina Solar's ongoing expansion plans include adding approximately 161,475 square meters to its existing facilities to increase its production capacity.

- Trina Solar sells and markets its products in number of European counties, such as Germany, Spain, Italy, Netherland, France, and Belgium, where government incentives have accelerated the adoption of solar power. Trina Solar also targets in emerging PV markets such as France, the United States, South Korea, India, Australia, China and Mongolia. Trina Solar sells its products to distributors, wholesalers and PV system integrators around the globe. HOW WE DO IT

- Trina Solar has successfully developed into a leader in the PV industry based on its strong, vertically integrated business model, producing its own ingots, wafers, cells and modules in-house. The control and efficiency achieved from this integrated value chain helps to continuously improve the production process as well as ensure high quality products to our end customers. This commitment to quality is one of the cornerstones of our long-term partnerships. As we are committed to improving efficiencies and competitiveness, we also look to partner with downstream companies who share those same values, working together to bring solar PV mainstream.

Trina Solar produces and commercializes a wide variety of photovoltaics (PV) modules, both monocrystalline and multicrystalline, with power outputs ranging from 165W to 230W. Adapting our product range to meet market demands allow us to provide our customers with a broader range of solutions.

SCHOTT Solar

SCHOTT POLY Solar Modules

SCHOTT Solar is a world leader in the photovoltaic

industry with more than 50 years of experience in the development and

production of quality components for solar applications. The company has

been in business for 125 years. The polycrystalline cells within each

module are sorted to narrow performance tolerances, thereby allowing

series interconnections with minimal mismatch losses.

SCHOTT POLY Solar Modules

SCHOTT Solar is a world leader in the photovoltaic

industry with more than 50 years of experience in the development and

production of quality components for solar applications. The company has

been in business for 125 years. The polycrystalline cells within each

module are sorted to narrow performance tolerances, thereby allowing

series interconnections with minimal mismatch losses.

- SCHOTT bulk packs modules to reduce job site waste and disposal costs. Available with black or clear anodized frames, SCHOTT modules have PV Wire type cables for use with transformerless inverters.

- Output ToleranceSCHOTT Solar POLY modules are among the industry leaders in power output tolerances. Produced in a facility in Albuquerque, NM, these modules are available in 4 wattages, with minus 0 watts output tolerance. This provides for a stable, high-energy output.

Kyocera Solar

Kyocera Solar Panels

Kyocera Solar Panels offered by Surya Solar are an

excellent choice for Grid-Tie and Off-Grid applications. We offer

Kyocera Solar Panels with MC connectors (GT) or a Junction Box (TM)

making them very adaptable to your needs. Kyocera solar panels with MC

Connectors are great for large arrays making it a snap to interconnect

large arrays or the handy Junction Box for making connections in a

weather tight box on the back of the solar panel.

Kyocera Solar Panels

Kyocera Solar Panels offered by Surya Solar are an

excellent choice for Grid-Tie and Off-Grid applications. We offer

Kyocera Solar Panels with MC connectors (GT) or a Junction Box (TM)

making them very adaptable to your needs. Kyocera solar panels with MC

Connectors are great for large arrays making it a snap to interconnect

large arrays or the handy Junction Box for making connections in a

weather tight box on the back of the solar panel.

- Kyocera is one of the world's largest vertically-integrated producers and suppliers of solar energy products.

- Kyocera solar modules are a reliable, virtually maintenance-free power supply designed to convert sunlight into electricity at the highest possible efficiency. Kyocera began researching photovoltaics in 1975 and has installed thousands of systems throughout the world since 1978. These systems are ideal for charging storage batteries to power remote homes, recreational vehicles, boats, telecommunications systems and other consumer and commercial applications.

- Kyocera's advanced cell-processing technology and automated production facilities produce highly efficient multi-crystal photovoltaic modules. To protect the cells from the most severe environmental conditions, they are encapsulated between a tempered glass cover and an EVA pottant with a PVF back sheet. The entire laminate is installed in an anodized aluminum frame for structural strength and ease of installation.

- The Kyocera KC130TM, 130 Watt Solar Panel and Kyocera KC130GT, 130 Watt Solar Panel are a couple of our most popular solar panels for a wide variety of applications.

ET Solar

ET Solar Group is a vertically integrated solar energy equipment manufacturer and turnkey solutions provider.

ET Solar Group is a vertically integrated solar energy equipment manufacturer and turnkey solutions provider.

-

With local sales and marketing

subsidiaries and offices throughout Asia, Europe, and North America, we

provide high quality photovoltaic modules, world leading solar tracking

systems and smart turnkey solutions to our customers in more than 50

countries and areas. Our products have been delivering strong operating

performance in a large number of residential and utility scaled solar PV

projects around the world.

- As one of the first solar energy turnkey solution providers from China, we have strong capabilities to tailor make the most efficient and economical solutions for our customers by factoring in a large variety of parameters such as project location, terrain condition, land size, land price, government subsidy and power density.

- Solar energy will become an essential component of the global energy portfolio in the foreseeable future and our fast growing trajectory showcases our commitment, strength and aspiration to be a significant contributor to the industry’s exponential growth in the next few decades.

LDK Solar

Overview

Established in 2005 in China, LDK Solar is the world`s

largest producer of solar wafers in terms of capacity and a leading

high-purity polysilicon and solar module manufacturer. The company has

expanded its business to meet the solar industry’s requirements for

high-quality and low-cost solar materials and solutions. As a vertically

integrated manufacturer and supplier of photovoltaic (PV) products, LDK

Solar has more than 15.000 employees worldwide. The Company’s

headquarters and manufacturing facilities are located in Hi-Tech

Industrial Park, Xinyu City Jiangxi Province in the People’s Republic of

China. LDK Solar maintains sales, marketing, and customer service

offices throughout Asia, Europe and North America.

Overview

Established in 2005 in China, LDK Solar is the world`s

largest producer of solar wafers in terms of capacity and a leading

high-purity polysilicon and solar module manufacturer. The company has

expanded its business to meet the solar industry’s requirements for

high-quality and low-cost solar materials and solutions. As a vertically

integrated manufacturer and supplier of photovoltaic (PV) products, LDK

Solar has more than 15.000 employees worldwide. The Company’s

headquarters and manufacturing facilities are located in Hi-Tech

Industrial Park, Xinyu City Jiangxi Province in the People’s Republic of

China. LDK Solar maintains sales, marketing, and customer service

offices throughout Asia, Europe and North America.

-

As one of the fastest growing solar

module providers in the world, LDK Solar has an established track record

of delivering consistently high quality solar modules to our valued

customers. We take pride in providing technologically advanced and

reliable solar modules and our product line is led by our passion to

design and deliver energy solutions that not only keep pace with global

needs, but anticipate them as well. We have three module manufacturing

facilities located in Nanchang City in Jiangxi province , Suzhou City in

Jiangsu province and Hefei City in Anhui province in China.

- LDK Solar manufactures and markets multicrystalline and monocrystalline wafers to manufacturers of solar cells and modules. Solar wafers are the principal raw material used to produce solar cells, which are devices capable of converting sunlight into electricity. The company also markets solar materials, which include ingots, and chemicals (used to produce Polysilicon and solar wafers) as well as provides wafer processing services.

- In 2009, LDK Solar expanded the scope of its vertical integration strategy to include sales of solar modules to developers, distributors and system integrators. LDK Solar acquired the crystalline module manufacturing plant of Best Solar in February 2010 to bring the manufacturing capability in-house.

- As part of LDK Solar’s vertical integration strategy, it constructed a polysilicon plant with two production facilities near its wafer production plants in Xinyu, China. The first facility has a planned installed annualized production capacity of 3,000 metric tons and the second facility has three separate 5,000 MT trains, for a planned 15,000 MT annualized production capacity. Combining the two polysilicon plants, LDK Solar expects to reach 18,000 MT capacity by the end of 2011.

Yingli Solar

Overview

Yingli is a leading solar energy company and one of the world’s largest vertically integrated photovoltaic manufacturers.

Overview

Yingli is a leading solar energy company and one of the world’s largest vertically integrated photovoltaic manufacturers.

Yingli Green Energy Holding Company Limited (NYSE: YGE), who holds the brand Yingli Solar, is a leading solar energy company and one of the world's largest vertically integrated photovoltaic manufacturers. We develop, manufacture and sell photovoltaic modules to a wide range of markets, including Germany, Spain, Italy, Greece, France, South Korea, China, and the United States.

-

With a balanced production capacity

of over 600 MW per year, our manufacturing covers the entire PV value

chain, from the production of polysilicon through ingot casting and

wafering, to solar cell production, and, finally, module assembly. We

commenced trail production at our in-house polysilicon facility in

December, 2009, with an initial production capacity of 3,000 metric tons

per year.

We supply high-quality PV modules under our brand name-Yingli Solar-to

utilities, system developers and integrators, distributors, and other

businesses around the world. Since we began commercial production in

2002, we have produced a total of 1 GW of PV modules.

- At Yingli, we are responding to the worldwide growing demand for renewable and affordable energy by supplying products that convert sunlight into electricity.

- We employ a balanced vertical integration strategy and utilize cutting-edge technologies to produce high-quality products with competitive cost structures. Maintaining both a global presence and local expertise, we are dedicated to serving our customers.

- We aspire to be socially and environmentally responsible in every decision we make. As a leader in sustainable energy solutions, we are proud of our mission: to make solar power an enduring and cost-effective technology for all humankind.

CCRES SOLAR List

This category contains listing of companies dealing in Solar Products and Components.

Join the movement!

Every day,

CCRES supporters fight to make environmental education, clean energy

solutions, and the green economy a reality.

Solar manufacturers offers various foundation options for the solar mounting systems including concrete piers, driven post, screw anchors and helical piles. All these options can work well; the developers and project engineers on the project must select the foundation that most efficiently works on the project in terms of design, engineering and economics. This is where experience in all types of foundation options becomes a key component in the overall design of the solar mounting system. Here are the benefits of using driven post as foundation for ground mount solar project.

OdgovoriIzbrišiEngineered solution for solar mounting systems:

Driven posts are a complete engineering solution. The quality is consistent from the first pile to the last and is tested prior to installation. Shape is maintained during installation. They do not bulge in soft soil conditions and are typically not susceptible to damage from the installation of subsequent piles. The pile driving process for solar mounting systems can be easily modeled prior to ground mount solar installation to determine adequate and economic equipment selection.

Economical solution for PV mounting systems:

Driven posts are usually the most cost effective foundation solution for ground mount solar. Pile capacity is easily verified by either static or dynamic pile testing. As an additional benefit, driven piles often gain capacity after installation.

Flexibility to mount solar structures:

Driven piles are installed to accommodate compression, tension or lateral loads. Piles can be selected to meet the specific needs of the solar structures , site conditions and budget.

Trustworthy and Available:

Pile driving equipment and installation methods are time-tested and well proven. Advances in materials, equipment, methods, and testing continually combine to improve the efficiency of driven post at solar panel installation .

Miscellaneous benefits of post driving for solar Racking systems:

Pile driving is relatively easy in many soils. Since the soil at the toe is in a compacted condition for displacement piles, end bearing can often carry a substantial load. Driven piles require no curing time and can be driven in natural sequence rather than skipping alternate piles, thus minimizing the moving of the equipment and speeding installation.

Environmentally Friendly:

Driven pile installations usually produce no spoils for removal and therefore no exposure to, or costly disposal of, potentially hazardous or contaminated materials. The site is left clean and ready for the next construction activity.

Great answer. I agree that Posts, Piles and Anchors are the way to go.

OdgovoriIzbrišiMy company, Mojave Industrial Tools, manufacturers COMPACT PILE DRIVERS just for the Solar Industry to use on their driven posts, screw anchors and helical piles. Just as the word "Compact" indicates the equipment is more manageable to use but yet has the Big power that is needed.

We have Track Units as well as Attachments for Skid steers, Backhoes and Excavators, to fit every need; i.e. size of project, type of soil, foundation anchors used, and mobility needed. We also have techniques to install posts & piles in difficult rocky soil and have tooling for Hard Rock.

Many EPSs and installers have asked us to develop a tool that installs IBeams/posts/piles with vibratory methods so no damage is done to the top of the post/piles, and this is now standard.

I would be happy to discuss this further with anyone needing Installation Equipment for their Solar Projects.

Kate Green

Mojave Industrial Tools www.MojaveIndustrialTools.com

sales@MojaveIndustrialTools.com

I really like looking at and I conceive this website got some truly utilitarian stuff on it!

OdgovoriIzbrišiSolar Racking Manufacturers

I like the way its been designed and the annexes and specifications are really helpful to understand the content.

OdgovoriIzbrišiSolar Racking Manufacturers

Good read! thanks for sharing.

OdgovoriIzbrišiSolar Power Installation Cost

Solar Panels In Las Vegas Nv